Setting up the organizational structure in SAP S/4HANA Material Management (MM) is a foundational step for ensuring efficient procurement, inventory control, and supply chain operations.

In this quick-start guide, we’ll walk you through how to configure SAP MM organizational units—including Company Code, Plant, Storage Location, and Purchasing Organization—in just 5 minutes.

Whether you’re an SAP consultant, MM functional analyst, or business user, mastering this setup is essential for successful MM module implementation and seamless integration with SAP FI, SD, and logistics processes. By the end of this tutorial, you’ll be able to streamline configuration, reduce deployment time, and align your SAP system with real-world enterprise structures.

Table of Contents

1. Master SAP S/4HANA Material Management in Just 5 Minutes!

Are you struggling to configure the SAP S/4HANA Material Management (MM) Organization Structure efficiently? Look no further! In this quick and step-by-step guide, we’ll show you how to set up MM Org Structure in just five minutes—saving you time and effort.

1.1 What You’ll Learn

In this guide, we will learn

- How to configure the MM organization structure rapidly

- Key settings for Plant, Storage Location, and Purchasing Organization

- Best practices to optimize SAP S/4HANA MM for efficiency and scalability.

💡 Watch this step-by-step tutorial to quickly configure the SAP MM Organization structure in 5 Minutes.

Time needed: 5 minutes

How to configure SAP S4 HANA Material Management Organization Structure in 5 minutes

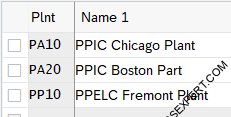

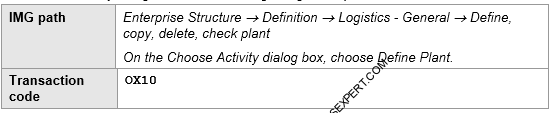

- Step 1 – Create Plants

Three Plants (PA10-PPIC Chicago Plant, PA20-PPIC Boston Part & PP10-PPELC Fremont Plant) Created

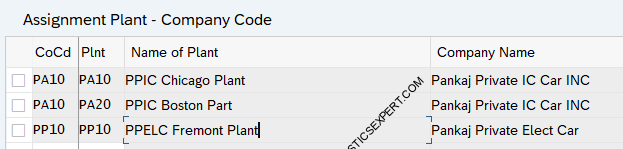

- Step 2 – Assign Plant to Company Code

(PA10 Plant ->PA10 Co. Code, PA20 Plant ->PA10 Co. Code, PP10 Plant->PP10 Co. Code)

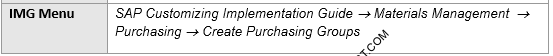

- Step 3 – Create Purchasing Groups

Four Purchasing Group (PA -Car Dealers, PB -Corporates, PC -Car Rental Companies, PD -Taxi Fleets) Created

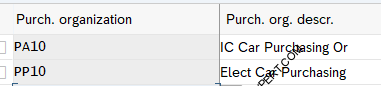

- Step 4 – Create Purchasing Organization

Two Purchasing Organization (PA10-IC Car Purchasing Org, PP10-Elect Car Purchasing Org) Created.

- Step 5 – Purchasing Scenarios

Three Purchasing Scenarios are explained

–> Scenario 1: Corporate-group-wide purchasing

–> Scenario 2: Company-specific purchasing

–> Scenario 3: Plant-specific purchasing

for our Car business Plant Specific Purchasing scenario is configured. Under this scenario

a) Assign Purchasing Organization to Company Codes

b) Assign Purchasing Organization to Plants. - Step 6 – Define Plant Parameters

(Check respective section below for details)

- Step 7 – Create Storage Location

(SLOCs are created, Check respective section below for details)

- Step 8 – Create MRP Controller

(Check respective section below for details)

- Step 9 – Create Material Groups

(Check respective section below for details)

Note

You can download the excel file from the below link to copy paste the values of all the steps while doing configuration

2. Configure S4 HANA MM Organization Structure

Let’s dive in and configure SAP S/4HANA MM Org Structure—faster and smarter!

2.1 Step 1: Create Plants.

In SAP S/4HANA Material Management (MM), a Plant is a vital component of an organization’s logistics structure, representing locations where goods are stored, produced, or distributed.

2.1.1 Why Is Plant Configuration Crucial?

Plant defined some of the very critical aspects of the supply chain, as given below

- Defines storage and production locations

- Enhances procurement and stock management

- Optimizes logistics and distribution workflows

The plant as an organizational structure works as follows

--> The plant is assigned to a single company code. A company code can have several plants.

--> Several storage locations in which material stocks are managed can belong to a plant.

--> A single business area is assigned to a plant and to a division.

--> A plant can be assigned to several combinations of sales organization and distribution channel.

--> A plant can have several shipping points. A shipping point can be assigned to several plants.

--> A plant can be defined as a maintenance planning plant.

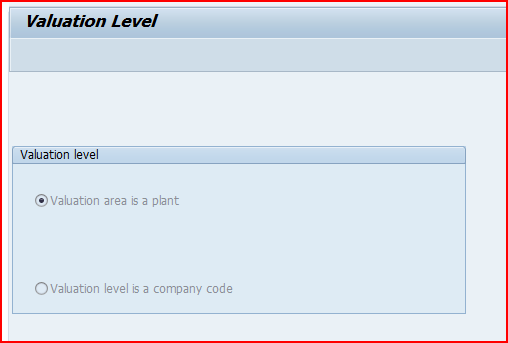

2.1.2 Plant as a Valuation Area

In SAP S/4HANA, the Valuation Area is a key component of Material Valuation, determining how inventory values are managed within an organization.

It defines the level at which materials are valued—either at the Company Code or Plant Level—directly influencing inventory valuation, accounting entries, and cost control.

SAP recommends Plant-Level Valuation, as it allows granular tracking of material costs across multiple plants, enabling accurate procurement pricing, stock valuation, and profitability analysis.

To declare plant as a valuation area, follow the below path

SPRO –> Enterprise Structure –> Logistics – General –> Define valuation level

Declare the plant as valuation area as shown in the below screenshot

2.1.3 Creation of Plants for Our Car business

We have created three plants for our car business

Follow the below path to create a plant

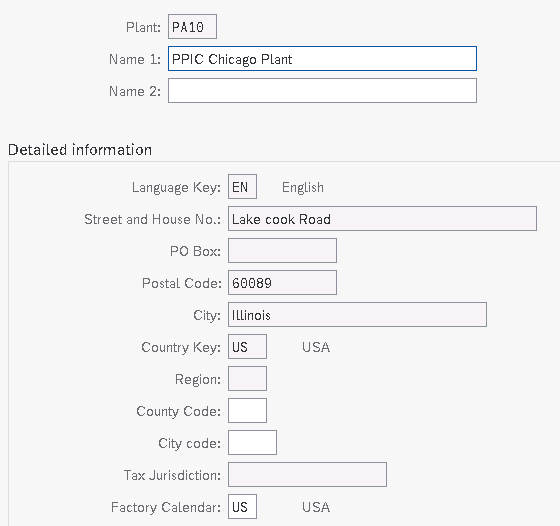

a) Creation of First IC Car Plant

The first plant PA10 manufactures petrol & Diesel cars. This plant is situated in Deerfield area of Chicago (IL).

Configure this plant as shown in the screenshot below

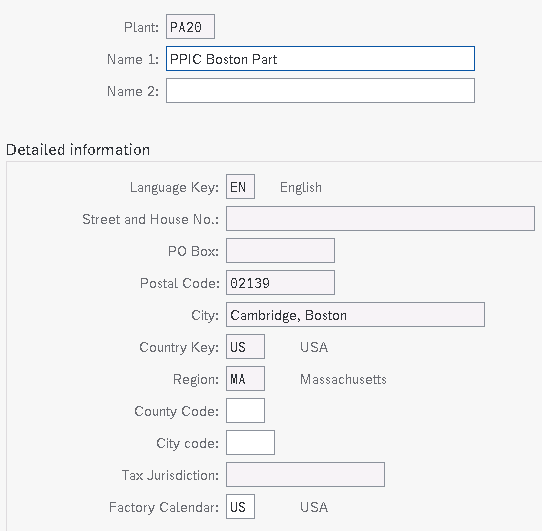

b) Creation of Second IC Car Plant

The second plant PA20 manufactures petrol & Diesel cars. This plant is situated in Boston (MA).

Configure this plant as shown in the screenshot below

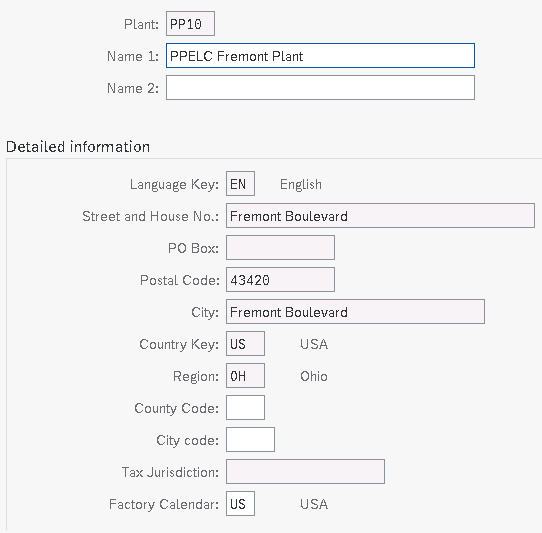

c) Creation of Electrical Car Plant

The first plant PP10 manufactures Electrical cars. This plant is situated in Fremont, CA.

Configure this plant as shown in the screenshot below

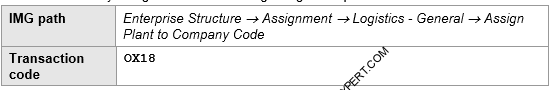

2.2 Step 2: Assign Plants to Company Codes.

In this step, we assign each plant to a company code. A plant can only belong to one company code.

Assign IC car Plants to IC Car Company Code & Electrical Car Plant to Electrical Car Company Code

Note

To Check the configuration related to company code pleas check Finance Organization Structure 5 Minutes Guide

This configuration plays a crucial role in deciding the nature of stock transfer between our plants, as explained below.

–> In the above configuration, plants PA10 & PA20 are assigned to the same company code (No need of having separate legal accounts etc.), The stock transfer between these plants will be an example of intracompany STO.

–> In the above configuration, plants PP10 & PA10/PA20 are assigned to the different company codes. The stock transfer between these plants will be an example of inter-company STO.

Please see the below post for the details on STOs

SAP Stock Transport Order Without Delivery: Process, Configuration & Guide

SAP Stock Transport Order with Delivery: Setup, Execution & Key Insights

How to Configure SAP Intercompany STO Process with Delivery & Billing

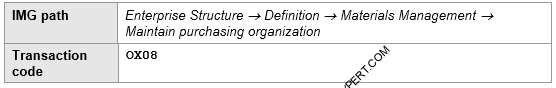

2.3 Step 3: Create Purchasing Groups.

We will efficiently Create Purchasing Groups in SAP S/4HANA MM. Purchasing groups play a crucial role in SAP S/4HANA Material Management, ensuring streamlined procurement processes and efficient vendor coordination. Configuring them correctly not only enhances supply chain efficiency but also optimizes purchasing strategies across your organization.

2.3.1 Importance of Purchasing Groups.

A Purchasing Group represents buyers or procurement specialists responsible for managing purchasing activities for specific materials or services.

Properly setting up purchasing groups enables:

- Better supplier management and negotiation leverage

- Improved procurement tracking and accountability

- Streamlined approval workflows for purchasing decisions

To create the Purchasing Group, follow the below path

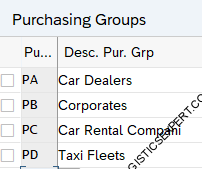

2.4 Step 4: Create Purchasing Organization.

Purchasing Organization is the backbone of procurement operations in SAP S/4HANA Material Management (MM).

Defining it correctly ensures efficient supplier management, cost-effective purchasing strategies, and smooth supply chain operations.

2.4.1 Importance of Purchasing Organization.

A Purchasing Organization is Important because:

- Controls purchasing activities at an organizational level

- Enhances vendor negotiations and procurement performance

- Enables better spend analysis and reporting

We have configured below purchasing organization for our car business.

2.5 Step 5: Purchasing Scenarios

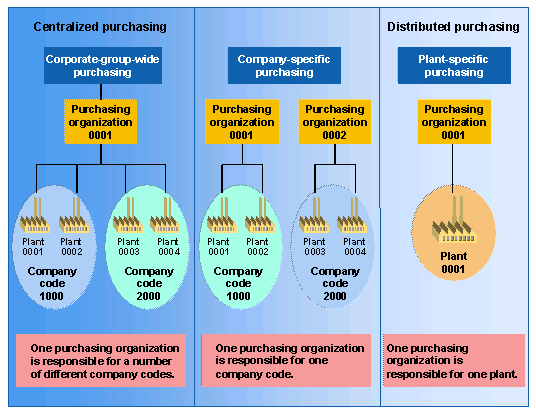

Three form of purchasing is possible in SAP

- Scenario 1: Corporate-group-wide purchasing

- Scenario 2: Company-specific purchasing

- Scenario 3: Plant-specific purchasing

2.5.1 Corporate-group-wide Purchasing

A purchasing organization is responsible for the purchasing activities of different company codes.

--> In this scenario, we do not assign a company code to the purchasing organization, but specify the company code concerned for each individual purchasing transaction. In configuration we assign the plants from different company codes to the purchasing organization.

2.5.1.1 Pros & Cons of Corporate-group-wide Purchasing

Below are the pros & cons of the Corporate-group-wide Purchasing

a) Pros of Corporate-group-wide Purchasing

- Economies of Scale: Bulk purchasing leads to significant cost savings through supplier discounts.

- Standardization: Ensures consistency in quality and pricing across the entire group.

- Stronger Supplier Relationships: Consolidated procurement gives leverage in negotiations.

- Process Efficiency: Streamlined procurement reduces administrative overhead.

b) Cons of Corporate-group-wide Purchasing

- Reduced Flexibility: Might not accommodate specific needs of individual plants or companies.

- Slower Decision-Making: Approval processes can be lengthy due to centralization.

- Risk Concentration: Dependence on fewer suppliers can pose risks in case of disruptions.

2.5.2 Company-specific Purchasing

A purchasing organization is responsible for the purchasing activities of just one company code.

--> In this scenario, we assign a company code to the purchasing organization. The purchasing organization may procure only for this company code. We assign only plants of the company code concerned to the purchasing organization.

2.5.2.1 Pros & Cons of Company-specific Purchasing

Below are the pros & cons of the Company-specific Purchasing.

a) Pros of Company-specific Purchasing

- Economies of Scale: Bulk purchasing leads to significant cost savings through supplier discounts.

- Improved Responsiveness: Faster decision-making and procurement cycles.

- Better Alignment with Business Goals: Purchasing decisions closely match company strategy.

b) Cons of Company-specific Purchasing

- Missed Bulk Discounts: Smaller orders may mean higher costs.

- Varied Supplier Relationships: May lack the negotiation power of Potential Inefficiencies: Duplicate efforts across different entities can increase costs.

2.5.3 Plant-specific Purchasing

A purchasing organization is responsible for the purchasing activities of one plant.

--> In this scenario, we assign the plant and the company code of the plant to the purchasing organization. The purchasing organization may procure for this plant only.

2.5.3.1 Pros & Cons of Plant-specific Purchasing

Below are the pros & cons of the Plant-specific Purchasing.

a) Pros of Plant-specific Purchasing

- Maximum Flexibility: Each plant can acquire materials suited to its production demands.

- Better Local Supplier Access: Plants can work closely with regional vendors.

- Fast Problem Resolution: Direct control allows quick responses to supply chain challenges.

b) Cons of Plant-specific Purchasing

- Higher Costs: Lack of bulk purchasing leads to increased expenditure.

- Resource-Intensive: Each plant requires procurement staff and systems

- Lack of Standardization: Variability in supplier contracts and pricing across locations.

The below picture depicts the different ways of organizing purchasing function in the SAP System

Courtesy : SAP Help

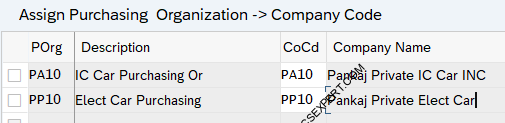

2.5.4 Purchasing Scenario for our Car Business

For our Car business we will configure “Plant Specific Purchasing” i.e. we assign the plant and the company code of the plant to the purchasing organization

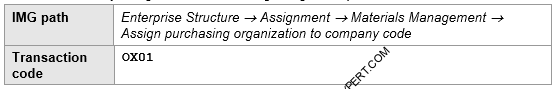

a) Assign Purchasing Organization to Company Code

Follow the below path to assign Purchasing Organization to Company Code

For our car business Purchasing Organization PA10 is assigned to Company code PA10 and Purchasing Organization PP10 is assigned to Company code PP10

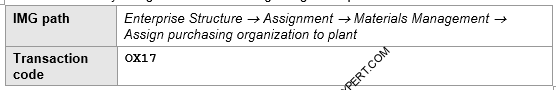

b) Assign Purchasing Organization to Plant

Follow the below path to assign Purchasing Organization to Plant.

For our car business Purchasing Organization PA10 is assigned to the plants PA10 & PA20. Purchasing Organization PP10 is assigned to the plant PP10.

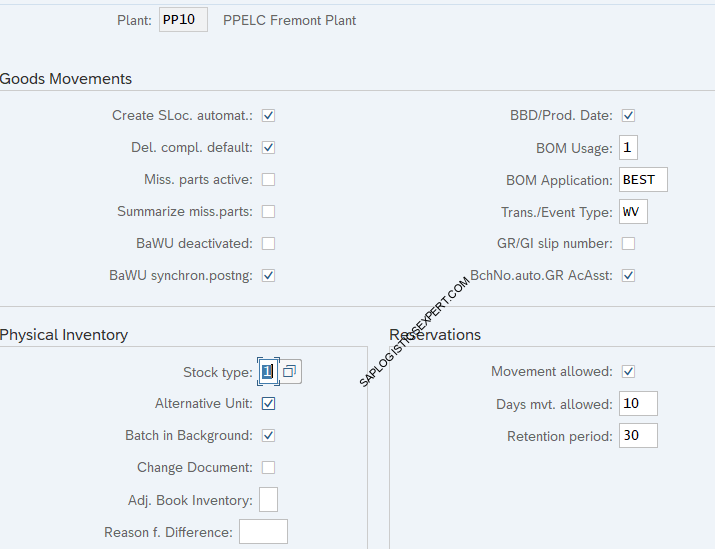

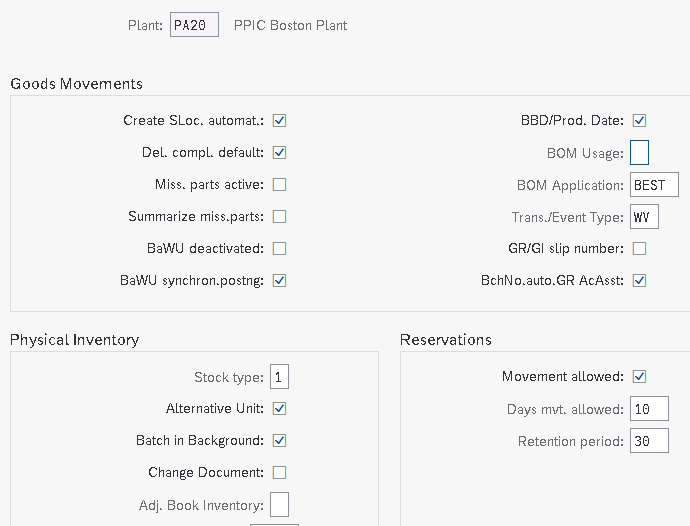

2.6 Step 6: Define Plant Parameter

Setting up Plant Parameters in SAP S/4HANA Material Management (MM) is essential for ensuring smooth logistics, inventory control, and procurement processes.

A properly defined plant parameter helps businesses optimize material flow, automate planning, and improve overall efficiency in supply chain management.

2.6.1 Importance of Plant Parameters

- Regulate material movement and inventory management

- Enable automated replenishment and procurement processes

- Optimize production scheduling and warehouse operations

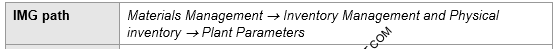

Follow the below path to configure plant parameters for our plants.

2.6.1 Define Plant Parameter for Plant PA10

Screenshot below is for the parameter for Plant PA10.

2.6.2 Define Plant Parameter for Plant PA20

Screenshot below is for the parameter for Plant PA20.

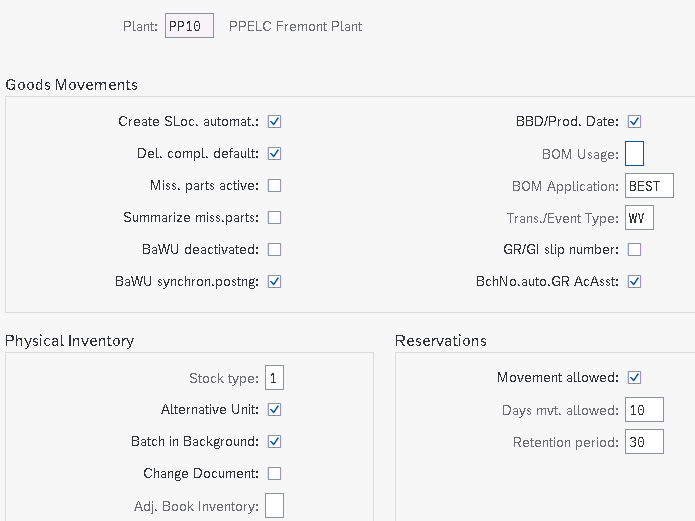

2.6.3 Define Plant Parameter for Plant PP10

Screenshot below is for the parameter for Plant PP10.

2.6.4 Explanation of Plant Parameters

We will review some of the important plant parameter

a) Automatic creation of storage location allowed

It Indicates that automatic creation of storage location data at the time of the first goods receipt is allowed.

Note : This should be allowed in the respective movement type also.

b) “Delivery completed” indicator

If this indicator is set, the system sets “delivery completed” indicator as a default value when a goods receipt is posted with reference to a purchase order or order .

Note : Quantity delivered should fall within the under/over-delivery tolerances.

c) Missing Parts Active

System check whether the material received is a missing part. If so, the system issues a warning and simultaneously sends a mail message to the MRP controller.

Note :Checking rules needs to be assigned to the transaction. Also missing parts checks and output determination functions have been set.

d) Check Best Before Date/Production Date

Indicates that the shelf life expiration date check at the time of goods receipts in the plant is active.

Note : For this , the expiration date check is active for the movement type & the minimum remaining shelf life has been defined in the material master record or in the purchase order

e) Automatic Batch no. assignment permitted for GR w. acct assgt

Indicates whether automatic batch number assignment is permitted when goods are received for a purchase order with account assignment for a material that is to be handled in batches

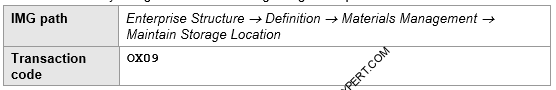

2.7 Step 7: Create Storage Location

A storage location is the place where stock is physically kept within plant.

Storage location has widely used in giving desired direction to the process. We have created several storage locations for our processess.

To create the storage locations, follow the below path

We have created below 14 storage locations for each of our three plants. These storage locations fulfill the different scenario requirements as given in the coming section.

2.7.1 Storage Locations for Various Scenarios

We have created 14 storage locations to fulfill different business scenarios. Lets explain one by one

a) Standard Storage Locations

We have created below three standard storage locations.

- PP1A : Standard Storage location 1

- PP1B : Standard Storage location 2

- PP1C : Raw Material

a1) Characteristics & usage of Standard Storage Locations

--> The first Storage location “PP1A” is the main Storage Location

The main storage location is where material is stored.

This is given in the “MRP 2” view of the material master

--> The second storage location “PP1B” is the Production Storage location

The production storage location is from where material is supplied to production and received from production.

This is given in the “MRP 2” view of the material master

--> We have used the Main storage location "PP1A" & Production storage location "PP1B" to demonstrate simple, standard production staging through MF60 --> Please check the below post to check the usage of standard storage locations in detail Material Staging for Production-Production Material Staging -Concept

Since these storage locations are standard storage locations so they have below charateristics

- Standard storage locations are Inventory managed only i.e. no WM or EWM managed

- There is no HU management activation

Please see the below post to check the standard storage location related business scenario configuration & testing in detail

SAP Storage Unit Management and Handling Unit Management – Scenario 1- Standard IM Managed SLOC

b) EWM Managed Storage Locations

These storage locations are connected to a EWM warehouse. These storage locations will be used for all the materials other than spare parts.

We have created below three SLOCs will be subjected to EWM

- PP1D : EWM Rec. on Dock : This EWM storage location represents the stock which is just received and not yet put away in the final storage BINs i.e. this stock is not available for outbound or any other movements in the warehouse.

- PP1S : EWM Available for Sale : This EWM storage location represents the stock for which put away in the final storage BINs are completed i.e. this stock is available for outbound or any other movements in the warehouse.

- PPSA : Prod SLOC : This storage location represents the stock which is available for to produce the final product in the production process.

b1) EWM Storage Locations for Spare Parts

We have created separate storage locations for spares parts because we want to have separate visibility for spare parts availability.

we have created below two storage locations for spare parts

Please see the below post to check the EWM configuration in detail

c) WM Managed Storage Locations

We have created below two storage locations for Warehouse Management (WM).

- PP20: SLOC with Warehouse Management (WM)

- PP22: SLOC with Warehouse Management (WM) & Handling Unit Management (HUM) mandatory.

New Use of the PP20 & PP22 SLOC

- PP20: HUM Partner SLOC

- PP22: SLOC with IM managed & Handling Unit Management (HUM) mandatory.

--> Since WM is now going to be obsolete so we will use WM managed storage locations (PP20 & PP22) for other use. --> We will use PP20 SLOC now as a IM HUM partner SLOC --> PP22 will be used as IM HU Managed SLOC same as PP21

d) HU Mandatory IM Storage Locations

These storage locations are standard (IM managed) but HU is mandatory i.e. stock can be managed only in HU in these storage locations.

We have created below SLOCs as HU Mandatory IM Storage Locations

- PP21: IM HU Mandatory SLOC

- PP22: HU Partner SLOC.

Please see the below post to check the standard IM with HU mandatory storage location related business scenario configuration & testing in detail

SAP Storage Unit Management and Handling Unit Management – Scenario 2- IM Managed SLOC with HU Management

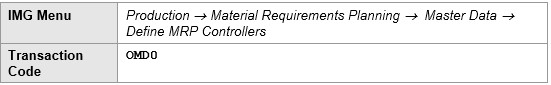

2.8 Step 8: Create MRP Controller

The MRP Controller in SAP S/4HANA Material Management (MM) plays a vital role in material requirements planning (MRP), ensuring accurate inventory control and smooth procurement processes.

By properly defining an MRP Controller, businesses can optimize production planning, reduce stock shortages, and improve operational efficiency.

The MRP controller is a person or a group of persons responsible for monitoring material availability.

2.8.1 Quick Steps to Create an MRP Controller in SAP S/4HANA

- Navigate to SAP S/4HANA Customizing (SPRO)

- Go to Materials Management > Material Requirements Planning > Master Data

- Define the relevant MRP Controller codes and attributes

Below MRP Controller are created for all our three plants

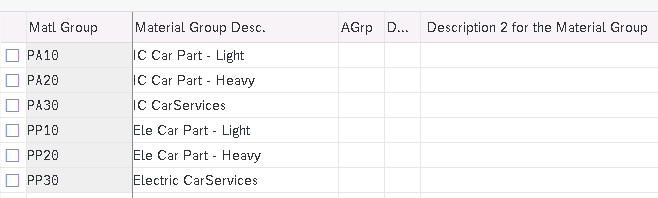

2.9 Step 9: Create Material Groups

In SAP S/4HANA Material Management (MM), Material Groups help classify products for efficient procurement and inventory control.

By properly defining these groups, organizations can optimize purchasing decisions, enhance reporting accuracy, and simplify material tracking.

2.9.1 Quick Steps to Create Material Groups in SAP S/4HANA

- Navigate to SAP S/4HANA Customizing (SPRO)

- Go to Materials Management > Material Master > Settings for Key Fields

- Define relevant Material Group codes and descriptions

Below Material Groups Have been created

We have completed S4 HANA MM Organization Structure.

In the previous post, we have configured minimum necessary Sales & Distribution Organization structure to run our business scenarios. Click on the above link to read in detail.

In the next post we will configure minimum possible Logistics Execution (LE) organization structure required to run our business scenarios. Click on the above link to read in detail

Pic Courtesy : Building photo created by freepik – www.freepik.com