Automatic Packing can be done in SAP for the below processes

- Automatic packing in Inbound Delivery

- Automatic packing in Production order

- Automatic packing in Outbound Delivery

- Automatic packing in Shipment

We will configure each scenario one by one.

Table of Contents

1. Elements to Pack Automatically in SAP

below are the elements to pack automatically in the SAP

How to Pack Automatically in SAP

- Step 1: Create/Choose Condition table

- Step 2: Define Access Sequence for Packing Instruction Determination

- Step 3: Define Determination Type/Condition Type for Packing Instructions

- Step 4: Define Procedure for Packing Instructions Determination

- Step 5: Maintain Packing Transaction Profile

- Step 6: Create Packing Instruction

- Step 7: Create Packing Instruction determination record

2. Automatic Packing in Inbound Delivery

Automatic packing in inbound delivery covers scenario such as

- Automatic packing in the goods receipt from the external supplier

- Automatic packing in the goods receipt through uploading onto a HU mandatory Storage Location.

We will now configure all the elements to enable automatic packing one by one.

2.1 Condition Table

In a condition table we define the combination of fields (for example, material and vendor), on which we want to make packing instruction determination dependent.

Note : We will fill this condition table with ‘contents’ (concrete entries) via the condition records, at a later point in time.

We will use below SAP standard tables

- Access Table 001 (Material)

- Access Table 400 (Material * Vendor)

- Access Table 410 (Material*Plant*Vendor)

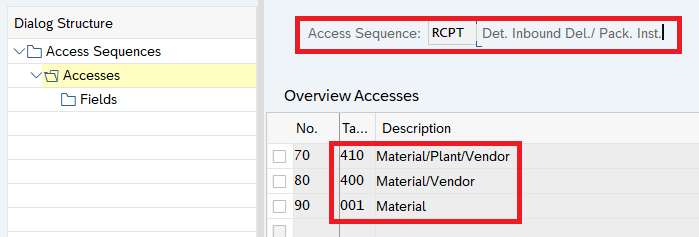

2.2 Define Access Sequence for Packing Instruction Determination

The access sequence is a search strategy that the system uses to search for valid determination records for a packing instruction determination type.

In our access sequence used for packing in inbound delivery, system searches for a packing instruction firstly via the combination of Material/Plant/Vendor (we defined this via the condition table 410), and subsequently via the combination of Material/Vendor (we defined this via the condition table 400) and then via Material only (we defined this in the condition table 001)

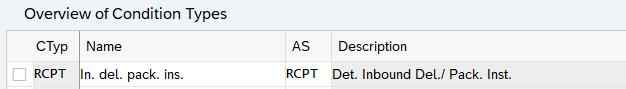

2.3 Define Determination Type/Condition Type for Packing Instructions

In this step we define specific determination types for packing instructions.

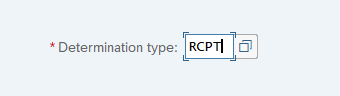

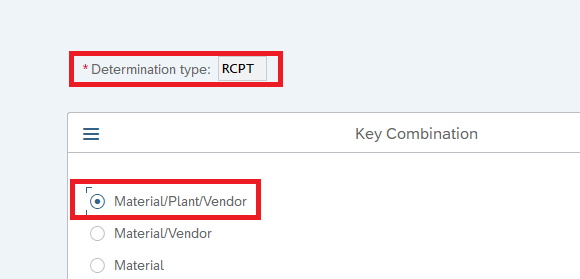

We will define Determination type “RCPT” for packing in inbound delivery and assign packing instructions to this determination type.

Note : Later on we will define determination records for a determination type.

SPRO –> Logistics – General –> Handling Unit Management –> Automatic Packing –> Determination of Packing Instructions –> Define Determination Type for Packing Instructions

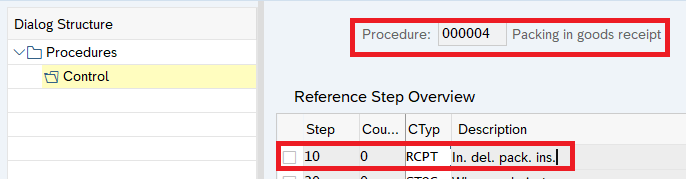

2.4 Define Procedure for Packing Instructions Determination

In a packing instruction determination procedure we define which determination types are used and in which sequence.

Procedure Used for Packing in Inbound Delivery

In our packing instruction determination “Packing in goods receipt”, the system uses the determination types “RCPT” contained in this procedure in sequence

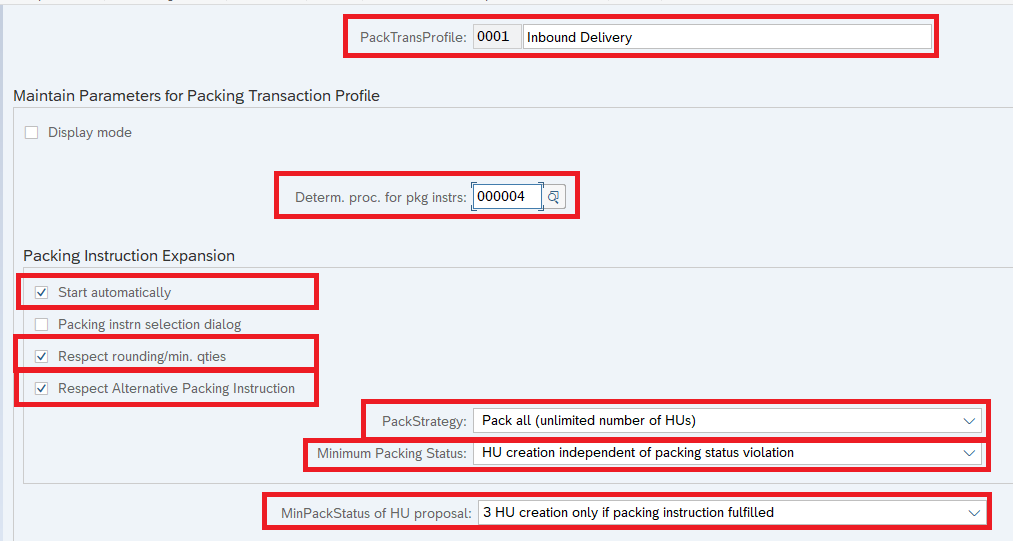

2.5 Maintain Packing Transaction Profile

Packing Transaction Profile is the grouping of parameters for the packing transaction as used in different areas.

There are different profiles for packing in Repetitive Manufacturing and in delivery. The profile defines parameters such as the determination procedure, the display mode, and the packing mode for the packing transaction when used in a specific area.

2.6 Delivery Related Configuration

We will configure automatic packing in inbound delivery generated in the process of goods receipt through 561 movement type for HU required storage location.

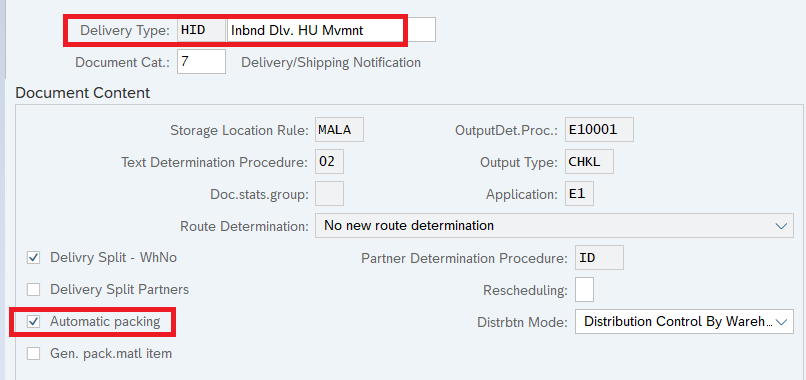

a) Activate automatic packing in Delivery Type

In this step we will activate Automatic packing for our targeted inbound delivery type “HID”

To know more about the configuration of HID Delivery type CLICK HERE

SPRO –> Logistics Execution –> Shipping –> Deliveries –> Define Delivery Types

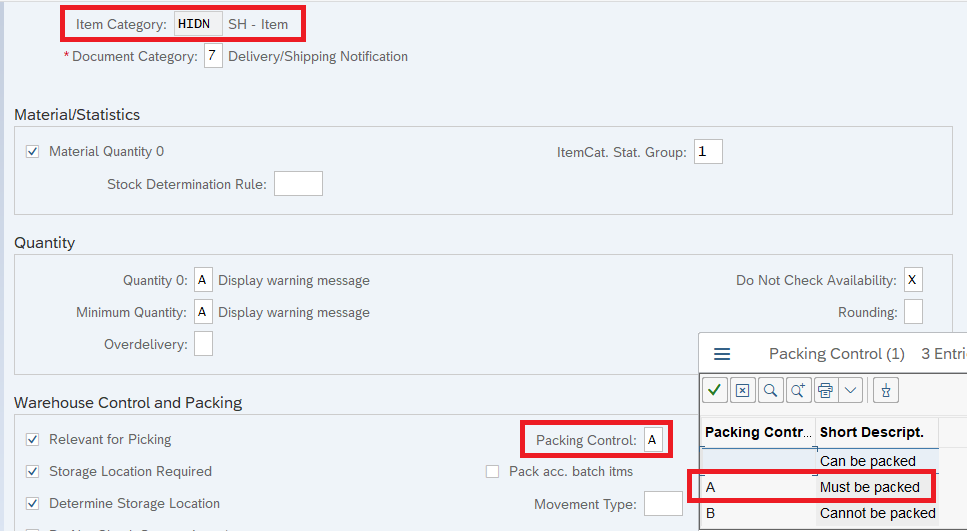

b) Activate automatic packing in Delivery Item Category

SPRO –> Logistics Execution –> Shipping –> Deliveries –> Define Delivery Item Categories

c) Create Packing Instruction

In packing instructions we tell the system what material is to be packed and through which corresponding packaging materials to be used for packing and quantity of the both materials.

Below is the packing arrangement for our one of component used in the BOM of the finished product

--> Component-Tail Lights (Material no.-500000007) will be packed into Packaging material Plastic Drum "PACK001" in 10 KG each and 18 such drums are packed on Pallet "PACK002" supplied by vendor

We will create two level packing instructions for this

c1) Packing Instruction First Level

First we will pack material 500000007 into Packaging material Plastic Drum “PACK001” in 10 KG quantity.

TCODE – POP1

c2) Packing Instruction Second Level

18 such drums (having material 500000007 into Packaging material Plastic Drum “PACK001” in 10 KG quantity) are packed onto Pallet “PACK002”

--> Second level packing instruction is built based on second level packaging material & first level packing instruction. Check the above screenshot highlighted part.

d) Create Packing Instruction Determination

This is used to find a suitable packing instruction to execute the automatic packing. This works on the principle of condition technique.

You can revisit the starting of the post to review condition technique used HERE

TCODE – POF1

Press enter

It will display all the three access tables used for our access sequence “RCPT”

2.7 Testing of Inbound Delivery Automatic packing

We will now test automatic packing

if we receive the material on a HU required SLOC (PP22 in our case), then system will create an inbound delivery of type “HID” as per our configuration HERE

Inbound delivery is created for 90 KG. Click on pack and system has automatically created 9 first level HUs packed onto 1 second level HU as per our packing instruction

Click on the “Pack” button as shown in the above screenshot and you can see system has automatic packed the material in the 9 first level HUs packed onto 1 second level HU as per our packing instruction

Image by upklyak on Freepik