In this post we will see step by step how to Configure Base PP Cycle in 5 Minutes.

--> As a functional consultant sometimes we want to configure a process quickly so that we can configure & test other dependent process. --> Here we are configuring PP cycles very quickly so that we can test further process like QM integration, WM Staging, EWM staging on top of it.

How to Configure Base PP Cycle in 5 Minutes

- Step 1: Create Bill Of Material (BOM)

- Step 2: Configure Production Order Type

- Step 3: Create Work Center

- Step 4: Create Routine

- Step 5: Create Production Version

- Step 6: Create & Release Production Order

- Step 7: Goods issue for Production order

- Step 8: Confirmation of Production Order

- Step 9: Good Receipt against Production Order

We will configure all steps in detail one by one in the following sections. Once we will configure & test all the steps given below, we will know in detail How to Configure Base PP Cycle in 5 Minutes

Table of Contents

Step 1: Create Bill Of Material (BOM)

BOM is a list of components and their quantities required to produce an assembly or a finished good.

1.1 BOM for Finished Product

our company produces cars so we will create a very high level BOM for out car company product “Car Model D”

BOM for Finished product “Car Model D”

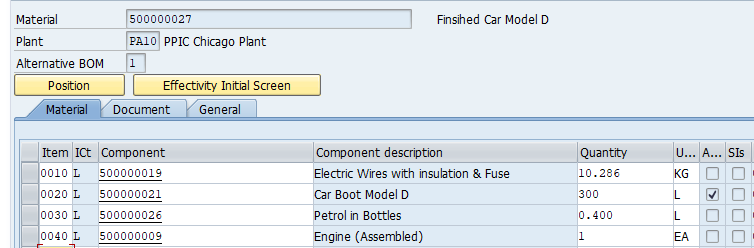

Finished Product (Car model D, Material Number 500000027) , 1 EA

- Component-Electric Wires (Material no.-500000019), 10.286 KG

- Assembly (Semi Finished)-Car Boot Model D (Material no.-500000021), 300 L

- Component-Petrol (Material no.-500000026), 0.4 L

- Component-Engine Assembled (Material no.-500000009), 1 EA

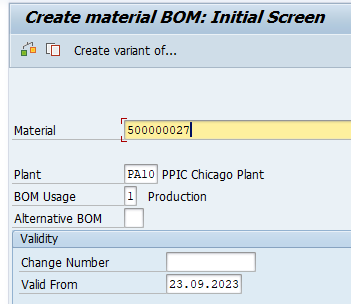

Run CS01 to create BOM

Enter plant as “PA10” & BOM usage as “1” (Production)

Press enter and now input all the 4 components as listed above

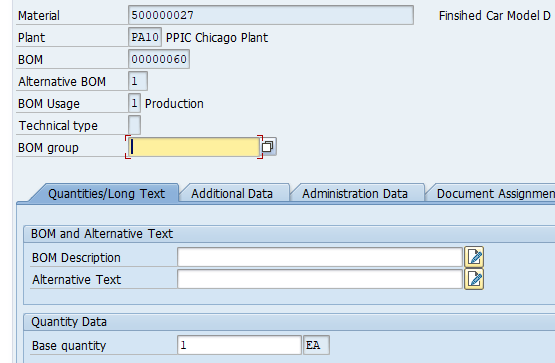

select Header and confirm that finished material qty is “1” i.e. this list of components and their respective quantities are required to produce 1 EA of finished goods.

1.2 BOM for Semi-Finished Products (Assemblies)

Since Car boot model D is a assembly so it will also be produced through its own BOM

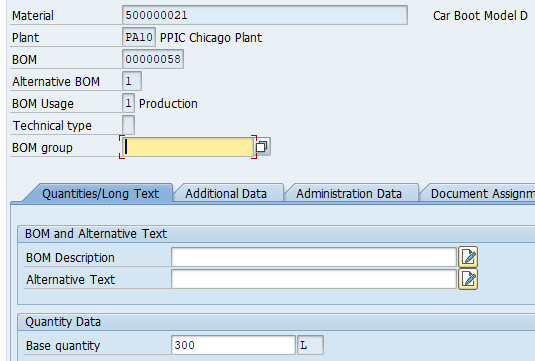

1.2.1 BOM for Assembly-1

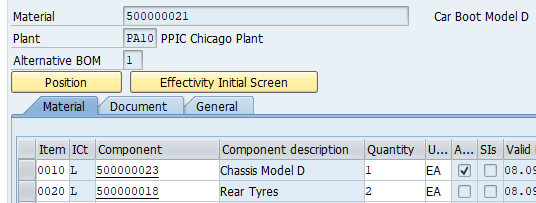

Assembly (Semi Finished)-Car Boot Model D (Material no.-500000021), 300 L

- Assembly (Semi Finished)-Chassis Model D (Material no.-500000023), 1 EA

- Component-Rear Tyers (Material no.-500000018), 2 EA

This BOM will look like below in system

Please check the qty of this assembly. This should be 300 L as 300L boot is required to product 1 car of model D

1.2.2 BOM for Assembly-2

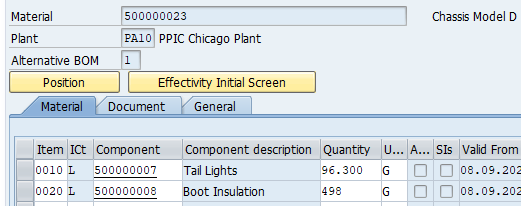

Since Chassis is also a assembly so it will have its own BOM

Assembly (Semi Finished)-Chassis Model D (Material no.-500000023), 1 EA

- Component-Tail Lights (Material no.-500000007), 96.3 G

- Component-Boot Insulation (Material no.-500000008), 498 G

This BOM will look like in the system as given below

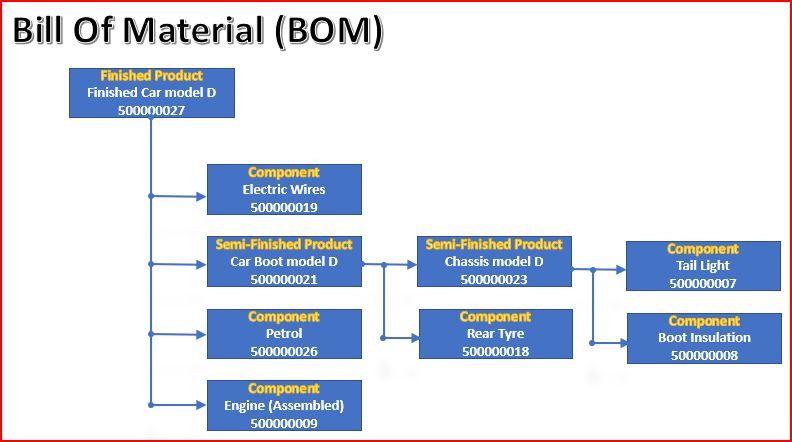

1.3 All the three BOMs in Pictorial Form

Below will be all the three BOMs in pictorial form

- BOM for FG (Car Model D)

- BOM-1 for SFG-1 (Car Boot Model D)

- BOM-2 for SFG-2 (Chassis Model D)

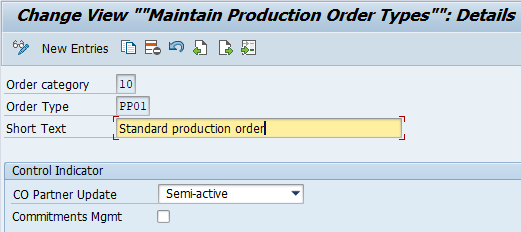

Step 2: Configure Production Order Type

We have to assign every order to a order type

Below is the path to configure Order Type

SPRO –> Production –> Shop Floor Control –>Master Data –> Order –> Define Production Order Types (OPJH)

We will use SAP standard order type PP01.

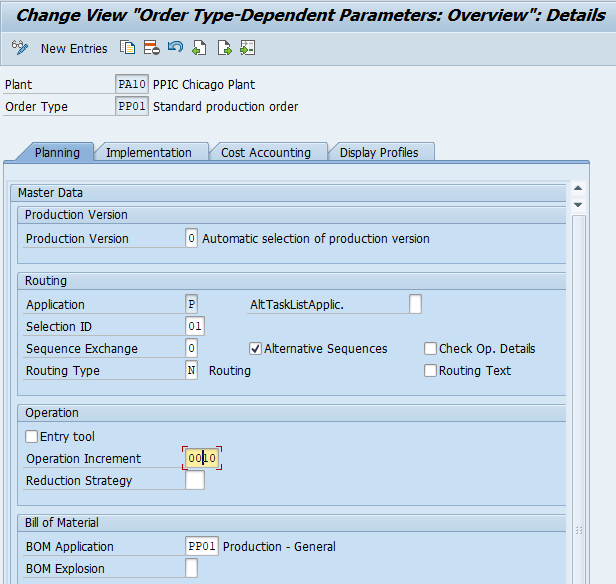

2.1 Define Order-Type-Dependent Parameters

Here we will Define the parameters for our order type (PP01) and plant PA10.

Below is the path to configure Order Type dependent parameters

SPRO –> Production –> Shop Floor Control –>Master Data –> Order –> Define Order-Type-Dependent Parameters for Production Orders (OPL8)

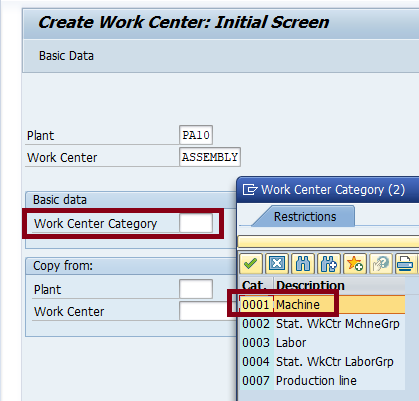

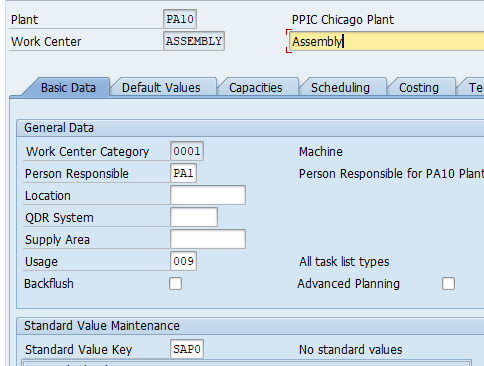

Step 3: Create Work Center

All the manufacturing activities are performed in the work center.

We will create three Work Center for our Car production

WC1 -ASSEMBLY

WC2-WORK (Final Work & Quality Inspection)

WC3-PACK01 (Packaging)

To create a WC , run Tcode CR01

Press enter and input further parameters as given in the below screen

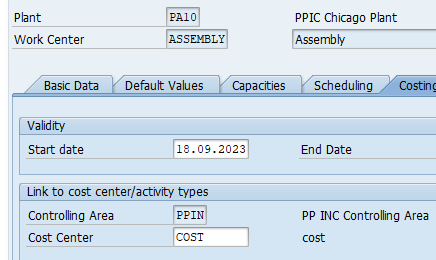

Under tab “Costing” input Controlling area as “PPIN” & Cost Center as “COST”

Note : Check the below link for controlling area Creation

Configure SAP Finance Organization Structure in 5 Minutes-Create Controlling Area

Click HERE to check the configuration of cost center accounting activation and creation of cost center “COST”.

Step 4 : Create Routine

Routine is list of activities which are performed for the production process in the form of a sequence of activities performed at the work center.

Routing plays an important role in costings etc.

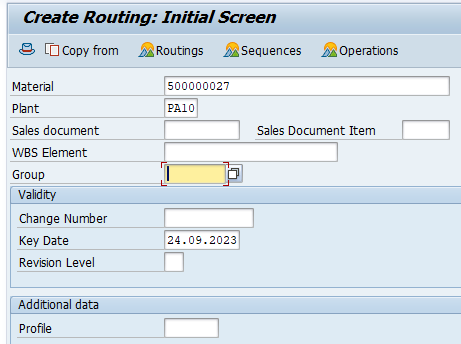

To create the routing start t-code CA01

Note: We can use grouping to group similar production processes and are used to produced similar materials.

give usage as “1” (Production) and status as “4” (Released)

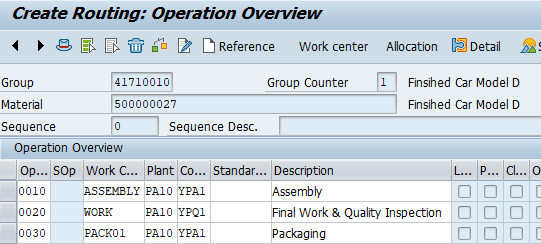

4.1 Routing for Finished Goods

Now input all the operations & their respective control key

For FG we will have three operations in the production process

- Operation 1: Assembly

- Operation 2: Final Work & Quality Inspection

- Operation 3: Packaging

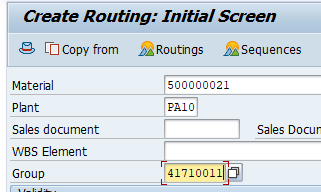

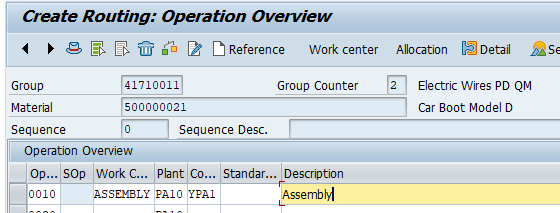

4.2 Routing for Semi-Finished Goods (SFG/Assembly)

For SFG we will have 1 operation in the production process

- Operation 1: Assembly

Input the WC, operation & Key

Routing is created now.

Step 5 : Create Production Version

A production version is used to determine the alternative BOM which is used together with task list/master recipe to produce a material or create a master production schedule.

We can have several production versions for a material for various validity periods and lot-size ranges.

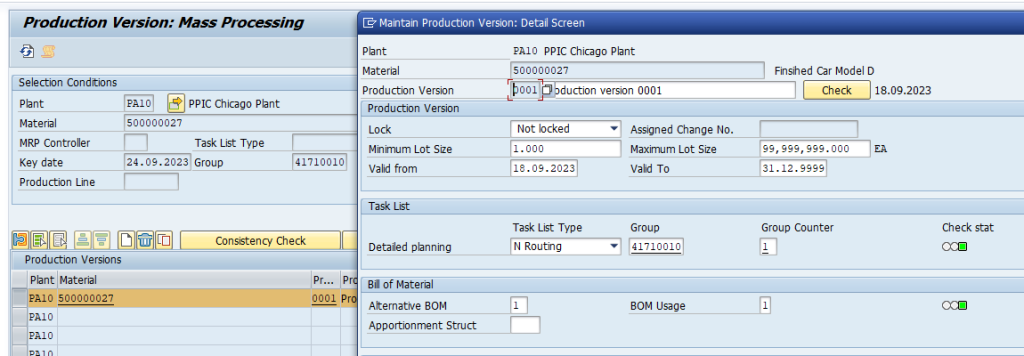

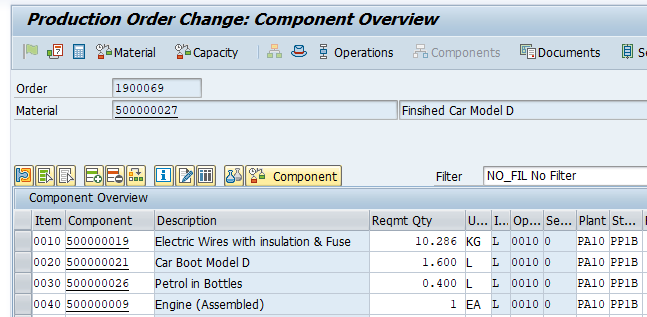

To create production version start t-code C223

5.1 Production Version for Finished Goods (FG)

input the same group as we used for routing

5.2 Production Version for Semi Finished Goods (SFG)

Create the production version for both of SFGs similarly. Used the same group which was used in SFG routing

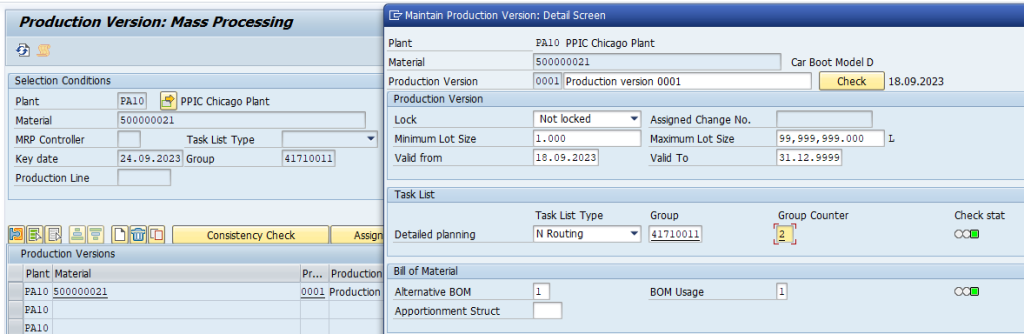

Step 6 : Create Production Order

Now we will create production order.

To create the production order go to CO01

Input the Finished material, Production plant as PA10 & Order type as PP01 (Explained HERE)

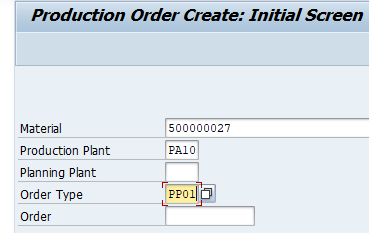

Press enter and click on Components

System will list all the components & respective quantities

as per the BOM

save & release the order

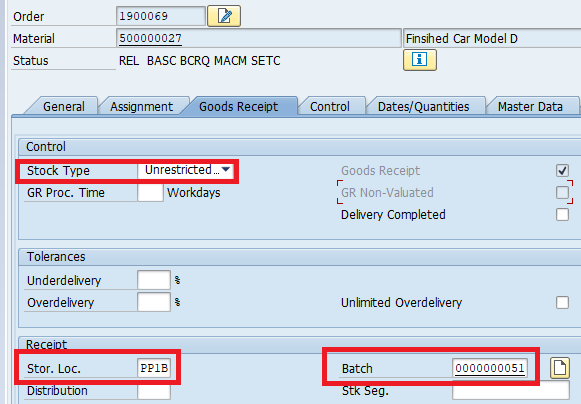

On the production order header system will create the batch of the FG which will be produced through this order .

Also there will be SLOC given (from the material master data) where this material will be received after production.

Stock type of the FG batch will be “Unrestricted” as we have not integrated it will QM

Check the below post for creation of FG for production order

2 Minutes Guide to Create your First Material in S4 HANA-Creation of FG for Production Order

Similar as per BOM (Detail HERE) create Raw material (ROH) & Semi Finish Materials (HALB)

Below materials are created

Assembly (Semi Finished)-Chassis Model D (Material 500000023)

- Component-Tail Lights (Material-500000007)

- Component-Boot Insulation (Material-500000008)

Assembly (Semi Finished)-Car Boot Model D (Material 500000021)

- Assembly (Semi Finished)-Chassis Model D (Material-500000023)

- Component-Rear Tires (Material no.-500000018)

Finished Product (Car model D, Material-500000027)

- Component-Electric Wires (Material-500000019)

- Assembly (Semi Finished)-Car Boot Model D (Material-500000021)

- Component-Petrol (Material-500000026)

- Component-Engine Assembled (Material-500000009)

Note:

Check the below post for creation of Semi-Finished goods (SFG) for production order

2 Minutes Guide to Create your First Material in S4 HANA-Creation of SFG for Production Order (HALB)

Check the below post for creation of Raw Material (ROH) for production order

Step 7 : Good Issue for Production Order

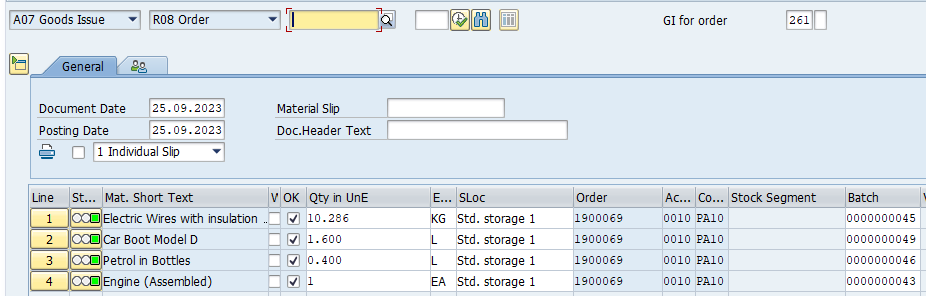

In this step we will do goods issue for production order

--> Material to be consumed for production is supplied from a storage location, which is called production SLOC --> If material to be used for production is stored in any another locations , while it is supplied to production to any other location then transferring to material from standard location to the production supply location is called "Production Staging"

At present standard storage location is the same as production storage location (which is given in the material master MRP2 view so we will not execute any staging before Goods issue to production order

Run Tcode MIGO to issue the material to production order

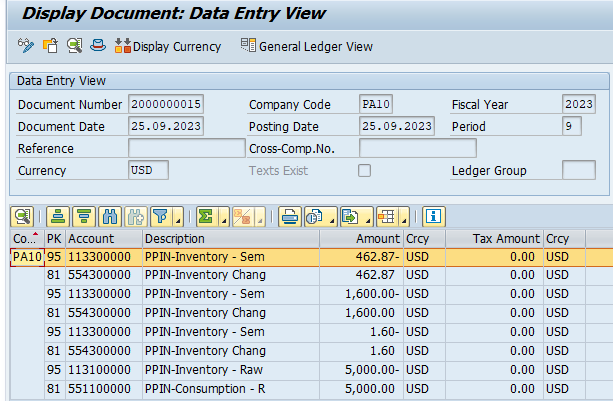

7.1 Production Order Goods Issue Accounting Document

Goods issue to production order is posted and accounting order is created

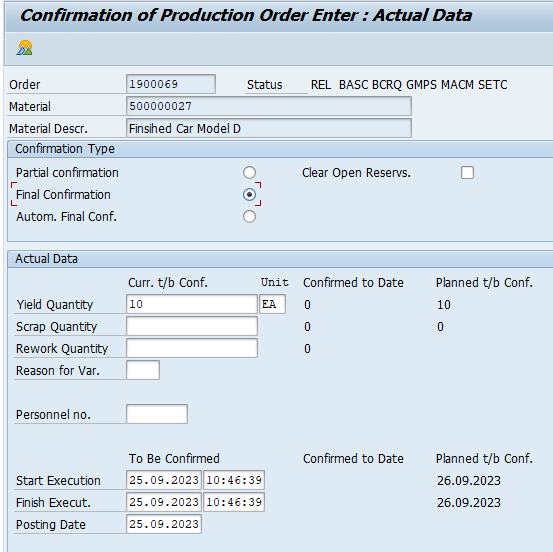

Step 8 : Production Order Confirmation

Now confirm the production Order

To confirm the production order run CO15

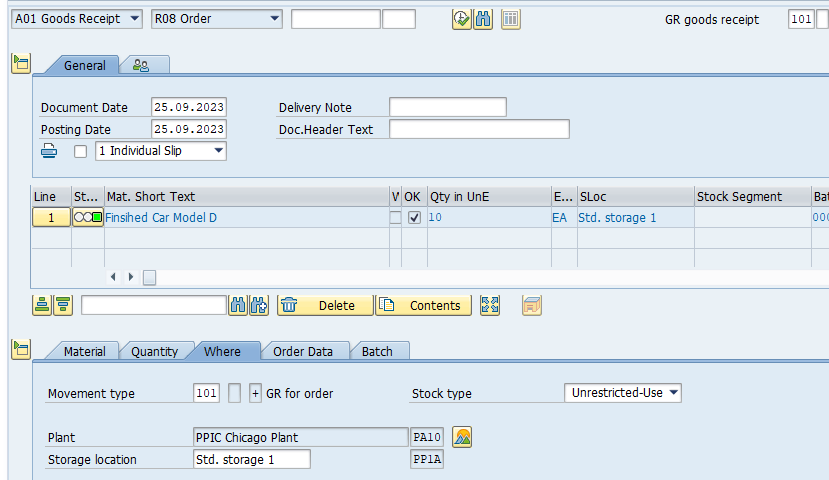

Step 9: Good Receipt against Production Order

Now we will receive the FG against production order. This will be received on the SLOC maintained in material master MRP 2 view

To receive the goods run tcode MIGO

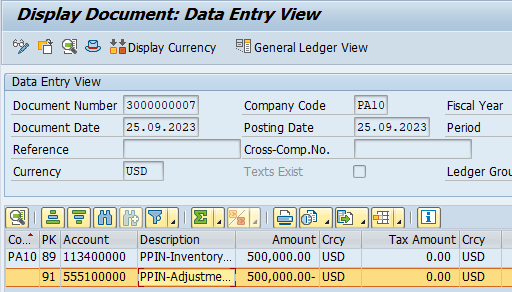

9.1 Production Order Goods Receipt Accounting Document

Check the accounting documents generated through Production order goods reciept.

Now we have configured and tested a very basic PP cycle without any staging, Quality integration, Wm integration etc.

Now we will configure & test several version of PP cycle with other scenarios on top of it

Image by macrovector on Freepik